VCR Investment Castings

VCR Investment Casting is a small but specialised company. We produce a large range of products some being for vintage cars and motorbikes, yachting, medical, safety equipment and engineering products. All castings are strictly manufactured to the customer`s specifications and standards. We pride ourselves on being reliable, delivering to specification in a timely manner. We produce in ferrous and non-ferrous alloys, alloy steel, aluminium and specialise in stainless steel 316 and 304 Grade.

Our Investment Casting facility is located in Brisbane, Australia and is family owned and run.

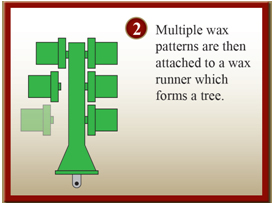

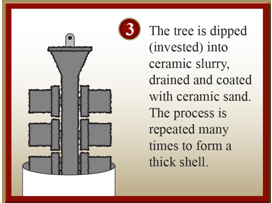

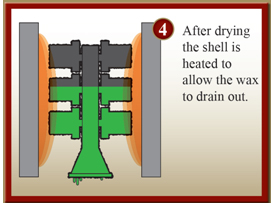

The Investment Casting Process

Investment casting is an industrial process also called lost-wax casting, one of the oldest known metal-forming techniques. It was used over 5,000 years ago when beeswax formed the pattern. With today’s high-technology waxes, refractory materials and specialist alloys, the castings process allow the production of components with accuracy, repeatability, versatility and integrity in a variety of metals and high-performance alloys.

By using the investment castings process, components are produced that require little or no further processing. We can produce complicated items that would be difficult or impossible to make by another manufacturing process by eliminating or substantially reducing the need for expensive machining or secondary operations. The process is capable of producing precise detail and dimensional accuracy of approximately +/-0.01mm of dimension in our components.

VCR Investment Casting has in-house tooling capabilities. Our fully trained toolmakers are experts in a wide range of manufacturing processing, which enable us to meet our customers’ expectation.

VCR Investment Casting works collaboratively with clients to design aluminium or epoxy aluminium dies, depending on the requirements for each customers components.

Request a quote to get more information on how our investment casting service can match your project requirements.

Our Address

Our Address  Contact Us

Contact Us  Phone

Phone